No products in the cart.

CM Specialist

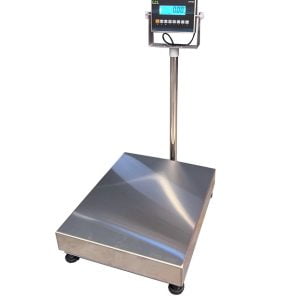

CM – TPS Series Pallet Scales

CM – TPS Series Pallet Scales

FEATURES:

- Big size LCD display, 52mm digits high, attached white color LED display

- Function include change weighing unit, net/gross shift, pre-tare, Accumulation

- Built-in rechargeable battery, up to 60 hours operate

OPTIONS:

- Built-in mini printer

CM EX – Proof Drum / IBC Filling Machines

CM EX-PROOF DRUM / IBC FILLING MACHINES

The ADF/CDF Series electronic Weight Controlled Drum Filling Machines provide accurate filling into the drums. Automatic Filling Lance descend and ascend movement cater for foaming and non-foaming product filling operation.

ADF/ CDF SERIES

AUTOMATIC DRUM FILLING MACHINES

Designed for Chemical/Oil/Food and Pharmaceutical IndustriesCM Fully Auto 200L Steel Drum Smart Labelling Machine

CM Fully Auto 200L Steel Drum Smart Labelling Machine

Designed to perform Auto elf Adhesive labelling on 200L steel drum body instantly while online with filling operations.

Customize to paste more than one label are available upon request.

Unique Features:

- Selectable Mid or Top Labelling Position

- Drum Surface Labelling Available Upon Request

- Parameter Setting for Different Label Size

- Touchscreen Display to Indicate Numbers of Counts with Limit Control

CM Fully Auto Pallet Filling Line

CM Fully Auto Pallet Filling Line

This Pallet filler is specially designed to operate and control of filling lance movement Operation works AUTOMATICALLY without any human operator guidance. Fully automatic from Parking the Empty Drum Pallet in position until 4 drums being filled. Hand Wheel and Gear Ratio design makes it effortless for Operator to adjust and set the height to Suit for different drums / IBC’s One Man Operation Filling Line.

- Built-in Camera System to address drum bunghole for filling operations.

- Automatic Shrink Wrapper installed inline with Pallet Filling Machine.

- All Integrated Interlocking Controls and Operations free from Human Operator interaction.

CM Fully Auto Single Steel Drum Filling Line

CM Fully Auto Single Steel Drum Filling Line

This auto drum filling line is specially designed to minimise the used of human operator and effort to perform multiple tasks operation. Automation which includes self-check after completed filling for each drum, and as well as data collection for each filled rum into a storage data base with an instant print QR or Barcode label auto paste on the drum body.

Enclosed Stainless Steel Cabinet to enhance Operations Safety and Contamination Control especially for food grade product or toxic chemicals filling. Easy access Electrical Panel and Metal Tab Seal Vibratory Dispensing Bowl for replenish Metal Tab Seal without interrupting filling operations.

CM Heavy Duty Industries Bench Scale LP7510C

Features:

- Aluminum or Stainless steel single point load cell

- Frame: Stainless steel or Mild steel

- Cover: Stainless steel

- Rectangular pole or 38mm diameter round pole

- Indicator function: total, tare, zero, hold, etc

- Resolution: n=3000 Option: n=6000,10000,15000

CM Heavy Duty Industries Floor Scale

Superior Structural Design

CM-Deck utilizes a full structural “C” channel frame welded to a durable steel deck, providing exceptional rigidity under severe loading conditions (typical of fork lifts and pallet jacks). This design has proven so superior that the CM-Deck carries a one-year warranty on the deck structure. The cross sections shown compare the deck structure of the CM-Deck with other low-profile floor scales. The placement of under deck supports on the CM-Deck minimizes deflection in all directions. Intermediate supports are added to prevent the top plate from “dishing” under heavy point loads.

Features

- Wide Range of customizable sizes and capacity

- Multiple built –

- Pallet Truck Access

- Forklift Access

- Pit Mounted

- Design technology allows for up to 300% safe overload

- Four units certified tool steel or stainless shear beam load cell

- Motion free design leveling foot with adjustable BALLFOOT support

- Threaded eyebolt holes for easy lifting

- Customize to customer require sizes

- Low profile construction

- Durable Construction for optional ramp, with non-skid imprint

- Large 6 digit LED display

- Dual scale operation(Optional)

- Stainless steel enclosure (IP65)

- OIML R-76 and NTEP approved

CM Model ABF Series Automatic Inline Volumetric Piston Filler

CM Model ABF Series Automatic Inline Volumetric Piston Filler

This CM Model ABF Series Multi Heads Inline Volumetric Piston Filling Machine is designed to fill liquid products of different viscosity, ranging from water, thin liquids like edible oil to semi viscous products like cream and lubricants oil. This Inline volumetric piston filling machine comes complete ranging from four to twelve filling heads, variable speed drive slat chain conveyor, and easy to read touch screen with electronic volume adjustment controls for speed and easy of setup.

MACHINE FEATURES:

- Motor powered driven automatic inline filler

- Suitable to fill higher viscosity liquids

- Automatic 2 stages filling speed control for fast/slow filling

- Automatic container neck locator and drip tray

- Touchscreen Panel provides Self-diagnostic Function

- No container No fill control

- Batch Container Counter

- Full microprocessor PLC controlled

- Piston pump volume available from 0.5 to 5 Lit

- Stainless Steel contact part suitable for food grade product filling

- Fully enclosed filling zone minimize dust contaminations

Common Use in Following Industries:

Petrochemical, Pharmaceutical, Biotechnology, Cosmetic, Healthcare and Personal Care etc…CM Stand Alone High Viscous Liquid Filling Machine

CM Stand Alone High Viscous Liquid Filling Machine

Semi Auto Ex-proof Open Top Pail Filling Machine Suitable for filling Solvent Based viscous liquid

Maximum Weighing Capacity up to 30kgs

Model: ADD-1P-30K-EX-LCSemi Auto Ex-proof Open Top Tin Filling Machine Suitable for filling Solvent Based viscous liquid

Maximum Weighing Capacity up to 15kgs

Model: ADD-IP-ISK-EX-PCSemi Auto Ex-proof Drum Filling Machine For Paint Suitable for filling Solvent Based viscous liquid

Maximum Weighing Capacity up to 300kgs

Model: ADF-4S-P-EXCrane Scale OCS – T

Crane Scale OCS – T

Features

- Low power consumption

- One-time charge can use for 150 hours

- Super bright LED display

- Simple operation, aluminum alloy housing

- Remote Control

Crane Scale OXS – XZ

Crane Scale OXS – XZ

Features

- Low power consumption

- One-time charge can use for 150 hours

- Super bright LED display

- Simple operation, aluminum alloy housing

- Remote Control

HOKUTOW – Digital Counting Scale

HOKUTOW – Digital Counting Scale

FEATURES

- 20 keys embossed membrane keyboard

- Quantity checking alarm and checking weighing, auto unit weight update

OPTIONS

- RS-232 can connect to computer, Lp-50 Label printer or TPuP mini printer

Hokutow – Digital Platform Scale

Features:

- Large LCD display with LED backlight

- Battery provide up to 90 hours of continuous use

- Programmable to meet your needs

- Function include counting, check weighing, animal scale, accumulation and weighing unit shift

Optional:

- Optional RS-232 communication interface, connect PC or LP-50 label printer, TPuP mini printer

IND570 Industrial Weighing Terminal

Ready to work

Performance and Versatility Delivered

Solutions for a Perfect Fit – Highly versatile in function. Constructed and approved for the harshest industrial environments. The IND570 is easily expanded with software, communication and control interfaces to meet process requirements – adding cost only when needed.

Flexible Control Options – Support for manual and automated weighing processes. Use operator routines to collect transaction data and guarantee consistency, quality and traceability. In automated systems, allow fast-updating digital I/O and integrated applications to take control, freeing operators for other assignments.

Secure, Efficient Access to Data – Convenient data management solutions provide data as you want it, when you need it. PLC, network, USB and standard serial communication interfaces available. Adapt data collection and transfer to meet the unique requirements of each weighing application.

Performance Monitoring – Improve system performance and avoid expensive down-time with proactive system monitoring. Smart, user-friendly diagnostic screens and reports provide important data to service personnel and system engineers, to help keep the system running at maximum potential.

IND570 Industrial Weighing

TerminalOne Terminal, Many Solutions –

Designed for performance and versatility, the IND570 industrial terminal is the easy choice for even the most most challenging industrial weighing applications.The IND570 features a broad offering of functions to manage weighing applications. Introducing advances in connectivity, performance verification and efficient, secure access to critical process data, the IND570 satisfies ever-increasing demand for measurement accuracy, reliability, efficiency and traceability.

IND780 Industrial Terminal

Power and performance

for advanced weighing applications

Graphics display with SmartTrac™ – Optimize the amount of visible process information with the QVGA graphical LCD display, available in monochrome or Active TFT Color. This helps to reduce operational errors and improves productivity.

Multitude of scale and communication interfaces – Various connectivity options for different scale interface technologies, PLC interfaces, Serial interfaces and Ethernet communications increases flexibility in meeting a combination of measurement and data integration requirements.

Stainless Steel Enclosure – Wall/Desk Mount enclosure style with IP69K rating ideal for pressurized cleaning and heavy washdown in food and pharmaceutical manufacturing environments.

Predictive Maintenance – Embedded predictive maintenance and diagnostics tools such as scale and load cell condition monitoring, calibration management, web server, error logs and email alerts.

IND780 Industrial Terminal

The IND780 is a terminal whose flexibility of configuration and fast multi-task processing makes it the perfect match for a wide range of specific applications. It features connectivity for multiple sensor technologies, networking, PLCs, and much more, and provides a platform for solutions that can be customized using the terminal’s basic functionality, optional applications, or the TaskExpert™ programming tool.VTS106 GDD POWERCELL Truck Scale

Containerized Steel Weighbridge

Accurate, Reliable and Easy to Maintain

POWERCELL® GDD® Load Cell – POWERCELL GDD load cells deliver unequalled accuracy and excellent reliability at an affordable price. The GDD system features individual load cell monitoring for easy maintenance and uses a CAN encrypted network to prevent fraud and cheating.

Easy Maintenance – The robust couplers and innovative checking system are designed for quick assembly

and easy maintenance. The middle cover can be removed for easy cleaning.Proven Performance – Using the unique “Module Masher” accelerated-lifecycle test stand, we test

every new weighbridge design at full design load. It is one way METTLER TOLEDO goes beyond the competition to ensure that you get the most reliable scale in the industry.Versatile Options – IND246, IND570 and IND780 terminals can be used with the VTS106 truck scale.

We also offer middle covers, side rail kits, ADI remote displays and vehicle software to meet the customer’s special requirementsVTS106 POWERCELL GDD Truck Scale –

The VTS106 POWERCELL truck scale is an economical product designed for applications with normal traffic volumes and over the road axle loads. This scale can be used in food, agriculture, oil & gas, and other seasonal applications. The simple but robust structure can last for more than 10 years.The POWERCELL GDD load cell (model number: SLC720) has a new design concept that takes vehicle weighing performance to a higher level. The load cell’s built-in microprocessor compensates for the effects of external changes, such as temperature, non-linearity, hysteresis, voltage fluctuation and creep. This digital compensation provides superior accuracy.

The entire weighing system also can be equipped with peripherals like printers, ADI remote display, PCs and with vehicle software to meet the customer’s specific requirements.

VTS107 PDX POWERCELL Truck Scale

Containerized Steel Weighbridge

Accurate, Reliable and Easy to Maintain

POWERCELL® PDX® Load Cell – POWERCELL PDX load cells are the best-in-class load cells for vehicle weighing with unequalled accuracy and reliability. The PDX system does not require junction boxes and each load cell is hermetically sealed for use in the toughest and most demanding environments

Easy Maintenance – The robust couplers and innovative checking system are designed for quick assembly

and easy maintenance. The middle cover can be removed for easy cleaning.Proven Performance – Using the unique “Module Masher” accelerated-lifecycle test stand, we test

every new weighbridge design at full design load. It is one way METTLER TOLEDO goes beyond the competition to ensure that you get the most reliable scale in the industry.Lightning Protection – The specially designed StrikeShield™ lightning protection system helps prevent

costly downtime by using multiple levels of protection to safeguard your entire scale system. It is the only system that has been tested by third-party laboratories and withstood multiple lightning strikes.VTS107 POWERCELL PDX Truck Scale –

The VTS107 POWERCELL truck scale is an economical product designed for applications with normal traffic volumes and over the road axle loads. This scale can be used in food, agriculture, oil & gas, and other seasonal applications. The simple but robust structure can last for more than 10 years.The POWERCELL PDX load cell (model number:SLC820) has a new design concept that takes vehicle weighing performance to a higher level. The load cell’s built-in microprocessor compensates for the effects of external changes, such as temperature, non-linearity, hysteresis, voltage fluctuation and creep. This digital compensation provides a highaccuracy weighing solution.

The entire weighing system also can be equipped with peripherals like printers, ADI remote display, PCs and with vehicle software to meet the customer’s specific requirements.