No products in the cart.

CM Specialist

CM – TPS Series Pallet Scales

CM – TPS Series Pallet Scales

FEATURES:

- Big size LCD display, 52mm digits high, attached white color LED display

- Function include change weighing unit, net/gross shift, pre-tare, Accumulation

- Built-in rechargeable battery, up to 60 hours operate

OPTIONS:

- Built-in mini printer

CM EX – Proof Drum / IBC Filling Machines

CM EX-PROOF DRUM / IBC FILLING MACHINES

The ADF/CDF Series electronic Weight Controlled Drum Filling Machines provide accurate filling into the drums. Automatic Filling Lance descend and ascend movement cater for foaming and non-foaming product filling operation.

ADF/ CDF SERIES

AUTOMATIC DRUM FILLING MACHINES

Designed for Chemical/Oil/Food and Pharmaceutical IndustriesCM Fully Auto 200L Steel Drum Smart Labelling Machine

CM Fully Auto 200L Steel Drum Smart Labelling Machine

Designed to perform Auto elf Adhesive labelling on 200L steel drum body instantly while online with filling operations.

Customize to paste more than one label are available upon request.

Unique Features:

- Selectable Mid or Top Labelling Position

- Drum Surface Labelling Available Upon Request

- Parameter Setting for Different Label Size

- Touchscreen Display to Indicate Numbers of Counts with Limit Control

CM Fully Auto Pallet Filling Line

CM Fully Auto Pallet Filling Line

This Pallet filler is specially designed to operate and control of filling lance movement Operation works AUTOMATICALLY without any human operator guidance. Fully automatic from Parking the Empty Drum Pallet in position until 4 drums being filled. Hand Wheel and Gear Ratio design makes it effortless for Operator to adjust and set the height to Suit for different drums / IBC’s One Man Operation Filling Line.

- Built-in Camera System to address drum bunghole for filling operations.

- Automatic Shrink Wrapper installed inline with Pallet Filling Machine.

- All Integrated Interlocking Controls and Operations free from Human Operator interaction.

CM Fully Auto Single Steel Drum Filling Line

CM Fully Auto Single Steel Drum Filling Line

This auto drum filling line is specially designed to minimise the used of human operator and effort to perform multiple tasks operation. Automation which includes self-check after completed filling for each drum, and as well as data collection for each filled rum into a storage data base with an instant print QR or Barcode label auto paste on the drum body.

Enclosed Stainless Steel Cabinet to enhance Operations Safety and Contamination Control especially for food grade product or toxic chemicals filling. Easy access Electrical Panel and Metal Tab Seal Vibratory Dispensing Bowl for replenish Metal Tab Seal without interrupting filling operations.

CM Heavy Duty Industries Bench Scale LP7510C

Features:

- Aluminum or Stainless steel single point load cell

- Frame: Stainless steel or Mild steel

- Cover: Stainless steel

- Rectangular pole or 38mm diameter round pole

- Indicator function: total, tare, zero, hold, etc

- Resolution: n=3000 Option: n=6000,10000,15000

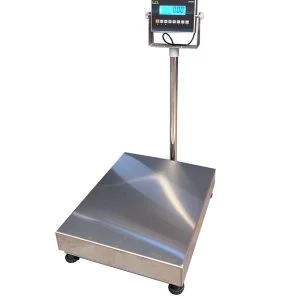

CM Heavy Duty Industries Floor Scale

Superior Structural Design

CM-Deck utilizes a full structural “C” channel frame welded to a durable steel deck, providing exceptional rigidity under severe loading conditions (typical of fork lifts and pallet jacks). This design has proven so superior that the CM-Deck carries a one-year warranty on the deck structure. The cross sections shown compare the deck structure of the CM-Deck with other low-profile floor scales. The placement of under deck supports on the CM-Deck minimizes deflection in all directions. Intermediate supports are added to prevent the top plate from “dishing” under heavy point loads.

Features

- Wide Range of customizable sizes and capacity

- Multiple built –

- Pallet Truck Access

- Forklift Access

- Pit Mounted

- Design technology allows for up to 300% safe overload

- Four units certified tool steel or stainless shear beam load cell

- Motion free design leveling foot with adjustable BALLFOOT support

- Threaded eyebolt holes for easy lifting

- Customize to customer require sizes

- Low profile construction

- Durable Construction for optional ramp, with non-skid imprint

- Large 6 digit LED display

- Dual scale operation(Optional)

- Stainless steel enclosure (IP65)

- OIML R-76 and NTEP approved

CM Model ABF Series Automatic Inline Volumetric Piston Filler

CM Model ABF Series Automatic Inline Volumetric Piston Filler

This CM Model ABF Series Multi Heads Inline Volumetric Piston Filling Machine is designed to fill liquid products of different viscosity, ranging from water, thin liquids like edible oil to semi viscous products like cream and lubricants oil. This Inline volumetric piston filling machine comes complete ranging from four to twelve filling heads, variable speed drive slat chain conveyor, and easy to read touch screen with electronic volume adjustment controls for speed and easy of setup.

MACHINE FEATURES:

- Motor powered driven automatic inline filler

- Suitable to fill higher viscosity liquids

- Automatic 2 stages filling speed control for fast/slow filling

- Automatic container neck locator and drip tray

- Touchscreen Panel provides Self-diagnostic Function

- No container No fill control

- Batch Container Counter

- Full microprocessor PLC controlled

- Piston pump volume available from 0.5 to 5 Lit

- Stainless Steel contact part suitable for food grade product filling

- Fully enclosed filling zone minimize dust contaminations

Common Use in Following Industries:

Petrochemical, Pharmaceutical, Biotechnology, Cosmetic, Healthcare and Personal Care etc…CM Stand Alone High Viscous Liquid Filling Machine

CM Stand Alone High Viscous Liquid Filling Machine

Semi Auto Ex-proof Open Top Pail Filling Machine Suitable for filling Solvent Based viscous liquid

Maximum Weighing Capacity up to 30kgs

Model: ADD-1P-30K-EX-LCSemi Auto Ex-proof Open Top Tin Filling Machine Suitable for filling Solvent Based viscous liquid

Maximum Weighing Capacity up to 15kgs

Model: ADD-IP-ISK-EX-PCSemi Auto Ex-proof Drum Filling Machine For Paint Suitable for filling Solvent Based viscous liquid

Maximum Weighing Capacity up to 300kgs

Model: ADF-4S-P-EXCrane Scale OCS – T

Crane Scale OCS – T

Features

- Low power consumption

- One-time charge can use for 150 hours

- Super bright LED display

- Simple operation, aluminum alloy housing

- Remote Control

Crane Scale OXS – XZ

Crane Scale OXS – XZ

Features

- Low power consumption

- One-time charge can use for 150 hours

- Super bright LED display

- Simple operation, aluminum alloy housing

- Remote Control

LP7510 – Hight Precision Weighing Indicator

LP7510 – Hight Precision Weighing Indicator

Features & Benefits:

- NTEP & OIML Approval

- Stainless steel or mild steel enclosure

- 6 digits 0.8″ LED or LCD display with backlight

- Key (OIML): ON/OFF Hold Total Count Gross Tare Zero Point

- Key (NTEP): ON/OFF Total Count Kg/b Gross Tare Zero Point

- Dives up to four 3500 load cells

- Automatic Power off

- Low-battery remind

- Dsiplay up to 30.000d

- RS232 port

RADWAG Analytical Balances AS 3Y

RADWAG Analytical Balances AS 3Y

- Balances AS 3Y series are laboratory weighing instruments featuring 5,7″ LCD colour touch panel which

provides new possibilities of balance operation and presenting measurement results. - Personalization of balance settings is carried out in extended user profiles. AS 3Y series comes standard with system of automatic adjustment using an internal mass standard. Level control is based on LevelSENSING system, RADWAG patented solution, which uses a system of an electronic level. New unction of AS 3Y series is online monitoring of ambient conditions through built-in sensors or an external ambient conditions module THB 2 series.

- AS 3Y series comes standard with esthetic weighing chamber protected by an anti-draft shield. Design of the weighing chamber enables easy disassembling of its glass parts, for keeping clean sterile.

- Interactive formulation mode in the AS 3Y series is a reliable tool for creating various mixtures with application of databases. Differential weighing mode aids mass control of the same sample subjected to differed processes over time. Extended databases enable storing all carried out measurements, with option of printing and exporting them.

- Standard and user defined printouts allow for maintaining documentation complying with

GLP/GMP requirements practically in any application. AS 3Y series features an independent mass control mode carried out with application of an automatic feeder PA-02/H

- Balances AS 3Y series are laboratory weighing instruments featuring 5,7″ LCD colour touch panel which

RADWAG AS.R Analytical Balances

RADWAG AS.R Analytical Balances

- The AS.R series represents a new standard level for analytical balances. They feature a new, readable LCD display which allows a clearer presentation of the weighing result. Besides, the display has a

new text information line allowing to show additional messages and data, e.g. product name or tare value. - Additionally, the new R series balances by means of pictograms signal the activated working mode, connection with the Internet, the battery charge level, balance service functions. Also a number of displayed measuring units has been increased.

- The balance precision and the measurement accuracy is assured by automatic internal adjustment, which takes into consideration temperature changes and time flow.

- AS.R series balances feature several communication interfaces: 2 x RS 232, type A USB, type B USB and optional WiFi. The housing is made of plastic, and the pan is made of stainless steel.

DATABASES IN R SERIES BALANCES – In new AS.R series balances the information system is based on 5 databases, which allows for several users to work with several products databases, and the registered weighing results can be subject to further analysis.

Quick access to information – Direct access to functions and databases is possible from the level of keyboard.

ALIBI memory – The used ALIBI memory is a data secure area and allows to record up to 100 000 weighment records. It ensures security of constant data register in the long time period.

- The AS.R series represents a new standard level for analytical balances. They feature a new, readable LCD display which allows a clearer presentation of the weighing result. Besides, the display has a

RADWAG PS.R2 Precision Balances

RADWAG PS.R2 Precision Balances

PS.R2 series balances represent a new standard of precision balances. They feature a new, readable LCD display which allows a clearer presentation of the weighing result. Besides, the display has a new text information line allowing to show additional messages and data, e.g. product name or tare value.

New PS.R2 balances, like previously designed PS series balances, have pans in two possible dimensions: 128×128 mm or 195×195 mm. balances with a smaller pan have a draft shield. The balance precision and the measurement accuracy is assured by automatic internal adjustment, which takes into consideration

temperature changes and time flow.PS.R2 balances feature several communication interfaces: 2 x RS 232, type A USB, type B USB and optional WiFi. The housing is made of plastic, and the pan is made of stainless steel. The balances have a possibility to weigh products out of the pan (under hook weighing) – the load hangs under the pan.

DATABASES IN R SERIES BALANCES – The information system is based on 5 databases, which allows for several users to work with several products databases, and the registered weighing results can be subject to further analysis.

Quick access to information – Direct access to functions and databases is possible from the level of keyboard.

ALIBI memory – The used ALIBI memory is a data secure area and allows to record up to 100 000 weighment records. It ensures security of constant data register in the long time period.